Tell me about what led to the decision for GLP to implement digital twins across the entire Czech portfolio. What sort of experience do you have with it?

I worked on Terminal 5 project in London from 2005 to 2007. I was in one of the production design teams leading a couple of the packages. We were coordinating parts of the buildings in a 3d model already then. It wasn’t called BIM then, but the building was extremely complex with numerous teams and design teams, and we had to fit it all together on site. The project was coordinated in a 3D model, including information we were putting into the model about the parts of the building. Back then, it wasn’t the main design tool, we were still designing in 2D — 3D was for coordination.

That just sounds like a lot of extra work.

It was extra work, but then it was well rewarded on site because as a result, the construction work happened with a minimum of clashes.

Isn’t that one of the biggest advantages of building with 3D digital project models? Minimizing mistakes and re-work?

It is. Another principle on that project site was no “hot works”, meaning no alterations were allowed. Everything had to be prepared off site. It had to be so well-designed and so well coordinated that we could just put it together. Everything had to fit. It was all about time, safety and money. Saving money, being faster, and saving material by doing the work right from the beginning. You invest more in the preparation, but then it pays off.

That was in 2005. When was the next time you worked on a 3D model that way?

That was in 2005. When was the next time you worked on a 3D model that way?

It was with a project for Skanska Property in Ostrava. An office building that never actually got built because of various issues. That was one of the first office projects developed in a 3D model and was designed by Hutni projekt Frydek Mystek. They had experience designing Indian manufacturing facilities and steel factories and keen to apply it to a real estate project.

Manufacturers seem to be far more progressive about their production methods. Elon Musk got rich by re-thinking what cars do and how they’re built. Why are the construction and property sectors so slow to adopt new methods like digital twins?

Construction isn’t as complex as the assembly of a car. If you invest in a 3D model of a car, you know you’ll save huge amounts of money and effort because you’ll use it to produce 5 million of them. Whereas each building is unique, and you change them along the way. But I agree that the industry is behind. We’re trying to catch up very quickly.

What’s holding up change?

One problem is when you ask suppliers if they work with BIM, they all say yes. But when it comes to the actual work, you realize that only 2% of them really understand it. The second problem is the implementation. If you develop a commercial building before you know who the customer is, you end up making changes along the way. Changing the 3D model is not as easy as changing 2D drawings. But it’s possible. The main challenge is to stay ahead of construction with the model. Very often, construction gets ahead of model creation.

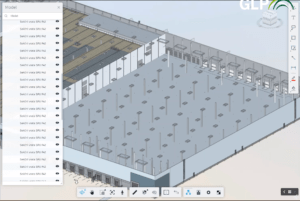

The real value of a digital model or digital twin comes when it’s kept up to date all the way until handover. Especially if it’s connected with all the technology installed in the building.

The real value of a digital model or digital twin comes when it’s kept up to date all the way until handover. Especially if it’s connected with all the technology installed in the building.

You get as much out of the model as you put in. But you have to understand that it’s not just a 3D model. It’s best to think of it as a 4D model with the fourth dimension being the information you add. So, if the model shows a pipe, it should also include information about what it’s made out of, or what pressure it can withstand. With moving parts, you need to know how often to check them. When parts break, you can tell from the model exactly what’s broken and what you need to replace it with. That information should be part of the model.

With your buildings, are you using digital twins to embed live data? For example, operational data from the HVAC system? Will you be using augmented reality or virtual reality applications to view the model?

It’s not there yet. The question is whether that’s the goal and what the visualization should look like. I don’t know if it should be about 3D goggles or if that’s a bit of science fiction. We should be careful to supply the industry with technology it will actually use, according to what’s feasible. We’re already providing a web-based interface for our customers, so they can see the performance of the buildings they lease from us. We give them the numbers and the graphs, but it’s their responsibility to analyze it and figure out that they left the heat on during the weekend.

We tend to think that everything has to be automated and controlled. I don’t think that’s the way forward. We’ve got to learn how to use data to our advantage and decide how we should adjust our own activities.

Also in ThePrime